When I set out to make chairs with carved seats, I quickly discovered how hard it was to find a travisher in Australia. The few available were mostly made overseas and came with hefty price tags and shipping costs. So, I decided to make my own.

Each of my travishers is crafted individually, one at a time, in my Sunshine Coast workshop. The blades are hand-forged from 80CrV2 steel for exceptional edge retention, while the bodies are shaped from Spotted Gum, a super hard-wearing Australian hardwood that can handle years of demanding use. The result is a tool that feels solid, balanced, and ready to work the moment it reaches your bench.

Designed with both woodcarvers and chairmakers in mind, the travisher excels at shaping and refining curves with speed and precision. Whether you’re sculpting a seat, coopering staves, or adding flowing details, it’s a tool that will quickly earn its place in your kit.

Because I’m a furniture maker myself, these tools are made in small batches between projects. That means lead times may vary from 1 to 6 months, but each travisher arrives sharp, tuned, and ready to use.

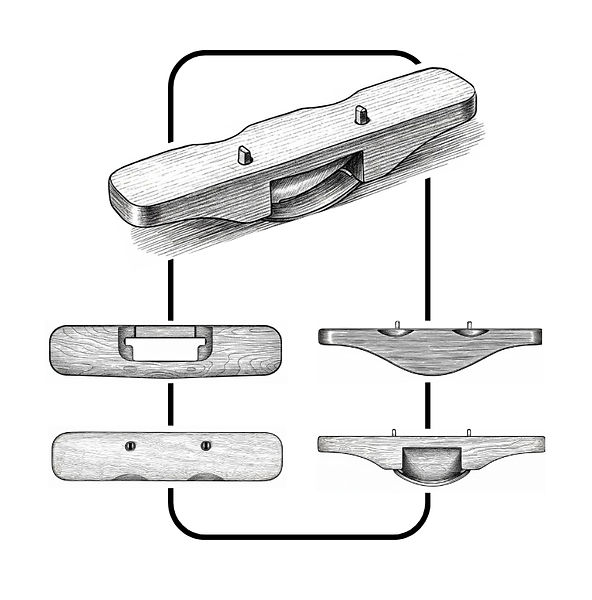

The first model of travisher I ever made, The Model #1 has a smaller, 60mm radius so best for removing large quantities of material with ease. This model is best for beginners and is the best "all rounder" when it comes to hollowing out concave surfaces.

I want woodworking and chair making tools to be accessible to as many people as possible, so The Model #1 has been designed to be the most affordable of the travishers with only two parts, the blade and the wooden body.

The Blade is held by friction and requires a gentle tap with a wooden mallet on the spine of the blade or tip of the tangs to adjust the depth of cut.

SPECS:

Blade - 80CrV2 Carbon Steel

Body - Spotted Gum

Radius - 60mm (2 3/8")

Friction fit tangs

60mm blade length

20 degree Bevel Angle

L - 210mm W - 45mm H - 45mm

Stamped and numbered

The Model #2 is the premium model of travisher with an ergonomic design, carved handles and a brass plate making the sole extremely durable. The blade is extremely easy to adjust with the use of two set screws, requiring a 2mm Allen wrench to turn the screws.

The Model #2 is just as useful as it is beautiful, making it the perfect option for collectors and craftspeople who take pride in their tools.

SPECS:

Blade - 80CrV2 Carbon Steel

Body - Spotted Gum

Radius - 90mm (3 9/16")

Fully adjustable tangs

70mm blade length

20 degree Bevel Angle

L - 240mm W - 45mm H - 65mm

Stamped and numbered

*Durable brass sole

*Ergonomic carved handles

If the travisher you want is not in stock, you can pre-order using the shop above. Lead times can be between 3-6 months.

Shipping cost are calculated at check out.

Shipping is currently only available in Australia.

For questions and enquiries contact info@benadams.studio

%20(Album%20Cover)%20(2).png)